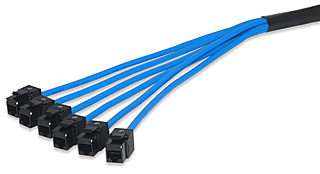

Category 5e Pre-Terminated Trunk Cable Assemblies

More Images

Pre-terminated Category 5e Trunk Assemblies help to reduce significantly both time and cost of a cabling installation. Terminated and tested in a controlled manufacturing environment, cut to the customer pre-ordered lengths, and ready to install in a patch panel, trunk assemblies eliminate all these operations in the field making your job easy and efficient. Trunk cable assemblies can be provided in an unscreened (U/UTP) and screened (F/UTP) versions in a jack-to-jack, jack-to-plug, or jack-to-blunt cut configurations to support the widest range of applications. Cables can be used with any Signamax field-configurable patch panel (screened trunk cables cannot be used with 48U-HDMMP-1R).

- Ready-to-use product – cable bundles are ready for installation and require no additional termina-tion operations except the one-ended designs

- Solid cable and keystone jacks used in the assembly meet and exceed category 6A specifications

- Pre-tested at the factory per ANSI/TIA-568-C.1 requirements

- All cable legs are labeled at both ends for easy identification and aligning in the field

- Each cable bundle is enclosed in a CMR- or CMP-rated mesh sleeve that retains the bundle and pro-tects it during installation

- Mesh sleeve is fixed by heat-shrink tubing that can be used as an anchor point when cable pulling is needed

- Compatible with all Signamax field-configurable patch panels (screened cables are not compatible with 48U-HDMMP-1R only)

- TRANSMISSION PERFORMANCE

ANSI/TIA-568-C.2: meets or exceeds category 6A (1-500 MHz) permanent link specifications

NOTE: All cable trunks require field testing after installation

- TRANSMISSION MEDIA

Unscreened: 100-Ohm twisted pair (U/UTP)

Screened: 100-Ohm twisted pair (F/UTP)

- JACK TYPE

8p8c (8-position, 8-contact) “RJ45” style, keystone design

- WIRING SCHEME

ANSI/TIA-568-C.2: T568B

- WIRE GAUGE

23 AWG, solid copper

- ELECTRICAL – JACK

Insulation resistance: min 500 MOhm @ 100 Vdc

Dielectric withstanding voltage: 1,000 Vdc/ac peak contact-to-contact @ 60 Hz for 1 min

Spring wire contact resistance: max 20 mOhm

IDC contact resistance: max 2.5 mOhm

- ELECTRICAL – CABLE

Spark test: 2,000 ± 250 Vac

Dielectric strength: 2,500 Vdc / 3 seconds

Insulation resistance: min 150 MOhm/km (46 MOhm/kft)

Conductor resistance: max 9.38 Ohm / 100 m (328 ft) @ 20 °C (68 °F)

Resistance unbalance: max 2 %

Capacitance unbalance: max 160 pF / 100 m (328 ft)

Mutual capacitance: max 5,600 pF / 100 m (328 ft)

- CONSTRUCTION – JACK

Housing:

unscreened: high-impact thermoplastic, UL94V-0 fire-retardant

screened: zinc-alloy fully shielded

grounding post for 2.5 x 0.5-mm (0.110 x 0.020-in) female disconnect

Jack spring wire: phosphor bronze alloy plated with 50 μin of gold over 70-100 μin of nickel

IDC: 110 type, phosphor bronze alloy with 100-μin 100% tin (Sn) alloy

- MOUNTING DIMENSIONS – JACK

Unscreened:

D 30.00 mm H 19.30 mm W 16.90 mm (D 1.181 in H 0.760 in W 0.665 in)

Screened:

D 42.40 mm H 25.80 mm W 16.90 mm (D 1.669 in H 1.016 in W 0.665 in)

- CONSTRUCTION – CABLE

CONDUCTOR:

Material: bare copper

Size: 23 AWG

Construction: 1/0.560 ± 0.02 mm (1/0.0221 ± 0.001 in)

INSULATION:

Material: CMR- or CMP-rated thermoplastic

Thickness: max average: 0.22 mm (0.009 in), min at any point: 0.12 mm (0.005 in)

Diameter: 1.0 ± 0.1 mm (0.039 ± 0.004 in)

Color coding:

blue/white-blue

orange/white-orange

green/white-green

brown/white-brown

Elongation: min 300 %

Tensile strength: min 1.682 kg/mm2 (0.0058 psi)

CENTRAL ELEMENT: CMR- or CMP-rated thermoplastic, cross-shaped

SHEATH:

Material: CMR- or CMP-rated thermoplastic

Diameter: 7.5 ± 0.3 mm (0.30 ± 0.01 in)

Color: see ORDERING INFORMATION

Elongation: min 100 %

Tensile strength: min 1.407 kg/mm2 (0.005 psi)

Thickness average: 0.65 mm (0.026 in), min at any point: 0.6 mm (0.024 in)

Aging: at 100°C for 168 hrs – min elongation retention: 50 %, min tensile strength retention: 75 %

SCREEN:

PET tape: 0.023 mm (0.0009 in) thickness

Aluminum/PET tape: 0.025 mm (0.0010 in) thickness

Tinned copper drain wire: 0.46 mm (0.018 in) diameter

- MECHANICAL – JACK

Total contact force: min 800 g for 8 wire leads

Retention force: 50 N (11 lbf) for 60 ± 5 s

Mating cycle life: min 750 cycles

- MECHANICAL – CABLE

Tensile strength: > 400 N (90 lbf)

Minimum bend radius: 25 mm (1 in)

- ENVIRONMENTAL CONDITIONS

Storage: -40 °C – +70 °C (-40 °F – +158 °F)

Operation: -10 °C – +60 °C (+14 °F – +140 °F)

RH (operation): max non-condensing 93 %

- COMPLIANCE

ANSI/TIA-568-C.2, IEC 60603-7, IEC 61156-6, IEC 60332-1-2, FCC Part 68 Subpart F, UL 94V-0, UL 444, UL 1666

- APPLICATIONS

X.21, V.11, S0, ISDN, CSMA/CD 10BASE-T, 100BASE-TX, 100BASE-T4, 100BASE-T2, 1000BASE-T, 10GBASE-T, TR 4/16/100, 100BASE-VG, ATM LAN 25/51/155, TP-PMD

- WARRANTY

5-year limited component warranty

10-year Signamax Link/Channel Warranty

15-year Signamax Extended Component Warranty

25-year Signamax Cabling System Warranty

Download Datasheet – Unscreened (PDF 646Kb) Revised 03.08.2011

Download Datasheet – screened (PDF 663Kb) Revised 03.08.2011

| Part Number | Description |

| 6L-C5E-JJ-R-FXXX | Category 5e 6-Leg Trunk Cable, Jack-to-Jack, Unscreened (U/UTP) Cable, CMR |

| 6L-C5E-JP-R-FXXX | Category 5e 6-Leg Trunk Cable, Jack-to-Plug, Unscreened (U/UTP) Cable, CMR |

| 6L-C5E-JB-R-FXXX | Category 5e 6-Leg Trunk Cable, Jack-to-Open, Unscreened (U/UTP) Cable, CMR |

| 6L-C5ES-JJ-R-FXXX | Â Category 5e 6-Leg Trunk Cable, Jack-to-Jack, Screened (F/UTP) Cable, CMR |

| 6L-C5ES-JP-R-FXXX | Â Category 5e 6-Leg Trunk Cable, Jack-to-Plug, Screened (F/UTP) Cable, CMR |

| 6L-C5ES-JB-R-FXXX | Category 5e 6-Leg Trunk Cable, Jack-to-Open, Screened (F/UTP) Cable, CMR |

For length substitute XXX for length in feet. Minimum length is 10 ft. Maximum length is 295 ft.

Unscreened cable color is blue. Screened cable is gray. Other colors are available.

Standard cable is straight cut for either left or right cable exit. Staggered cut cables are available.

For riser-rated (CMP) cable substitute P for R in P/N.